by Anthony Roth, Greenhouse Manager

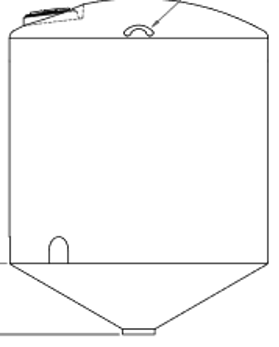

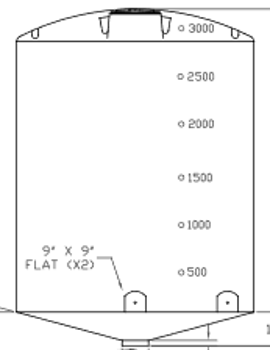

Quality Liquid Feeds’ commitment to research was expanded in 2021 with the tank farm located at the QLF Agronomy Research Center in Dodgeville, WI. The tank farm currently consists of three 15 degree cone bottom tanks and three 30 degree cone bottom tanks. Each tank has three different ways to recirculate (over the top, through a mixing eductor, and an air chuck with a valve). Each bank of three tanks is connected to a filter and bypass system that allows recirculation without going through the filter and then with the turn of two three-way valves, the product can be filtered before leaving the system. One of the goals of the tank farm was to evaluate the 15-degree cone tanks and the 30-degree cone bottoms. The other part of this study looked at the three different ways to recirculate in these different cone bottoms.

Results

When comparing the 15-degree cone bottom versus the 30-degree cone bottom the 30-degree bottom cleaned 60% better. At the end of the two-month-long evaluation, the contents of the tank were pumped into an empty tank and we measured what remained in the bottom. On average there were about 22 gallons that remained in the tanks. This study utilized over-the-top recirculation. When looking at setting up a new system, I would recommend a 30-degree cone bottom because of the easier cleanout and because the 30-degree cone bottoms are easier to access the bottom valves.

The recirculation evaluation consisted of over the top, through a mixing eductor, and air through the bottom of the tank. This study showed that each method had some advantages and disadvantages when compared together. Over the top method was the fastest as far as gallons per minute (70 GPM), however, it was the least effective in keeping a homogenous mix. The mixing eductor was the slower option (50 GPM). The mixing eductor also creates a plume and a vortex-like tornado in the cone creating aggressive mixing motion. It also was advantageous in cleaning the slope of the cone when emptying the contents of the tank. Finally, the air through the bottom was the quickest with only needing to hook up an air hose and open a valve. 5 to 10 psi was all that was needed to bring the liquid to a rolling bubble action. Some places would not have access to an air compressor making this option not possible.

The research tank farm has proved useful in evaluating different liquid handling capabilities and provides a place to demonstrate these to growers and dealers as well. If you’re looking to get set up with a liquid system to handle our L-CBF products, contact your local QLF RSA to assist you with your equipment needs.