by Steve Echelmeier, Regional Sales Manager Idaho

Most large dairies are achieving high milk yield and components by ensuring their herd is receiving a high quality and consistent ration. A computer program for tracking feed inventory, loading, delivery, and refusals is often incorporated, modern feed mixing equipment is utilized, and feeder training is ongoing. However, very few are aware of the many missed opportunities for improvement that still exist when a TMR quality control (QC) audit is done on their feeding program.

The Project

In 2019, 16 Idaho dairies participated in TMR QC audits as a part of the Quality Liquid Feeds Summer Intern Program. These dairies were not only selected for their high level of production but for their innovation and desire to become even more efficient producers of milk.

For each dairy, the TMR from one high-cow pen and the prefresh (or close-up) pen were sampled at the time of feeding at five evenly spaced locations along the bunkline. They were sampled again at the same locations four to eight hours later and again at sixteen to twenty hours after feeding. Each sample was subsampled twice. One sample was sent for nutrient analysis while the other was subject to a Penn State Shaker Box Test.

Brinno cameras were installed along the bunklines of the two pens for a duration of 48 hours to monitor cow activity, eating patterns, and bunk scoring. In addition, a GoPro camera was mounted on the TMR mixer during the loading, mixing, and delivery of the original feed for both pens in order to track mixing thoroughness and effectiveness of the mixer.

The Results

Generally, most rations in the bunk were not far off from the nutritionist’s paper rations when the five samples along the bunk were averaged. There were some exceptions to this, of course. However, most of the ration variances observed were among the five samples along the bunkline.

Utilizing the GoPro video footage, we were able to confirm that the TMR was not sufficiently mixed at delivery, as high amounts of corn came out at the end of the batch, providing a very different ration than what was delivered along the rest of the bunk. GoPro video footage also aided in determining the dry minerals added to the mixer were not evenly dispersed along the bunk line which could lead to production, health, or reproductive problems in the herd. These types of bunkline variabilities were not uncommon among the dairies audited. Ten out of the sixteen herds had room for improvement in this category.

TMR sorting measurements revealed several areas to be improved upon in the majority of the diaries as well. Below our Brinno cameras confirmed this was the case, as we were able to see the cows nose out the long stem, unprocessed forage and select the smaller grains and byproducts after the feed was pushed up only 30 minutes prior (snapshot below).

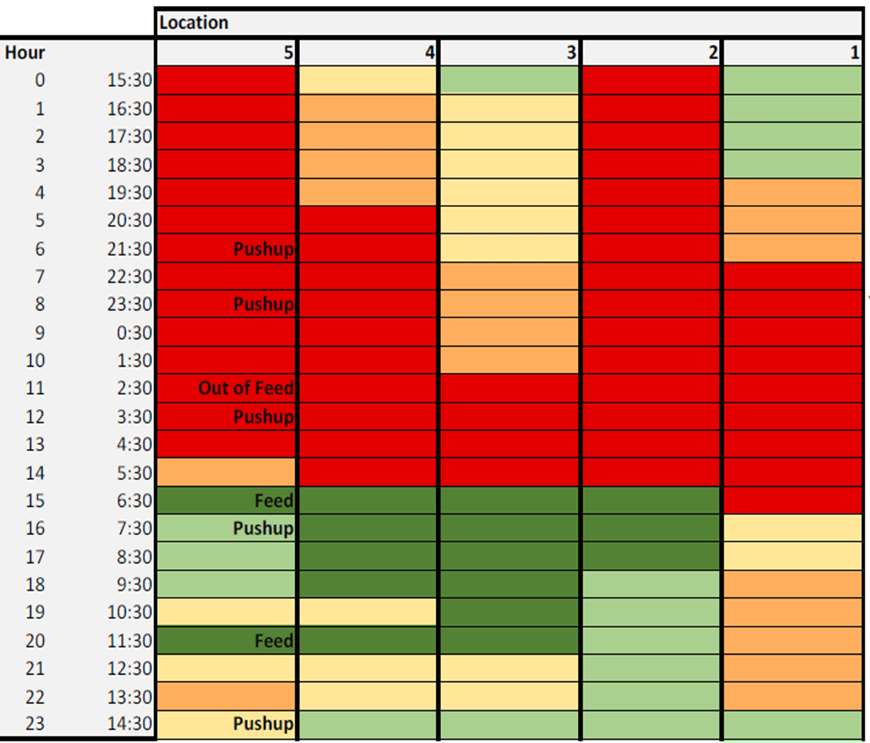

Perhaps the biggest opportunity for improvement noted among the 16 dairies audited was the ability to keep fresh feed in front of the cows throughout the day and night. The picture above was very common among all herds. This particular herd was out of feed by midnight. And as indicated on the chart below and the amount of red (out of feed) squares, they were not fed again until 6:30 am the next morning. In fact, they were what we and the producer agreed to be too low on feed for the majority of that day and the next. Most producers in these audits were aiming for 2-3% refusals and were ok with cows running out of feed for an hour or two before the morning feeding time. However, these audits showed most high cows to be out of feed for four to eight hours before their next feeding.

Summary

These 16 dairies are doing many things correctly and have proven as much with their level of milk production and herd health, however every dairy we audited still had room for improvement. Providing a properly processed, well – mixed, and evenly distributed TMR that is available to all cows for at least 23 hours per day is the goal. It may take a TMR QC audit to root out any problems that the dairy producer may not even be aware of in order to reach that goal.

For a complete review of these studies and intern projects, please contact your local QLF Representative.